Since 1996, Rahul Enterprises has delivered world-class precision metal stamping and tooling solutions for the automobile, electrical, electronics, and automation sectors. Powered by cutting-edge machinery and decades of expertise, we bring your designs to life — efficiently and accurately.

We provide innovative, high-precision sheet metal solutions tailored to meet the diverse needs of global industries.

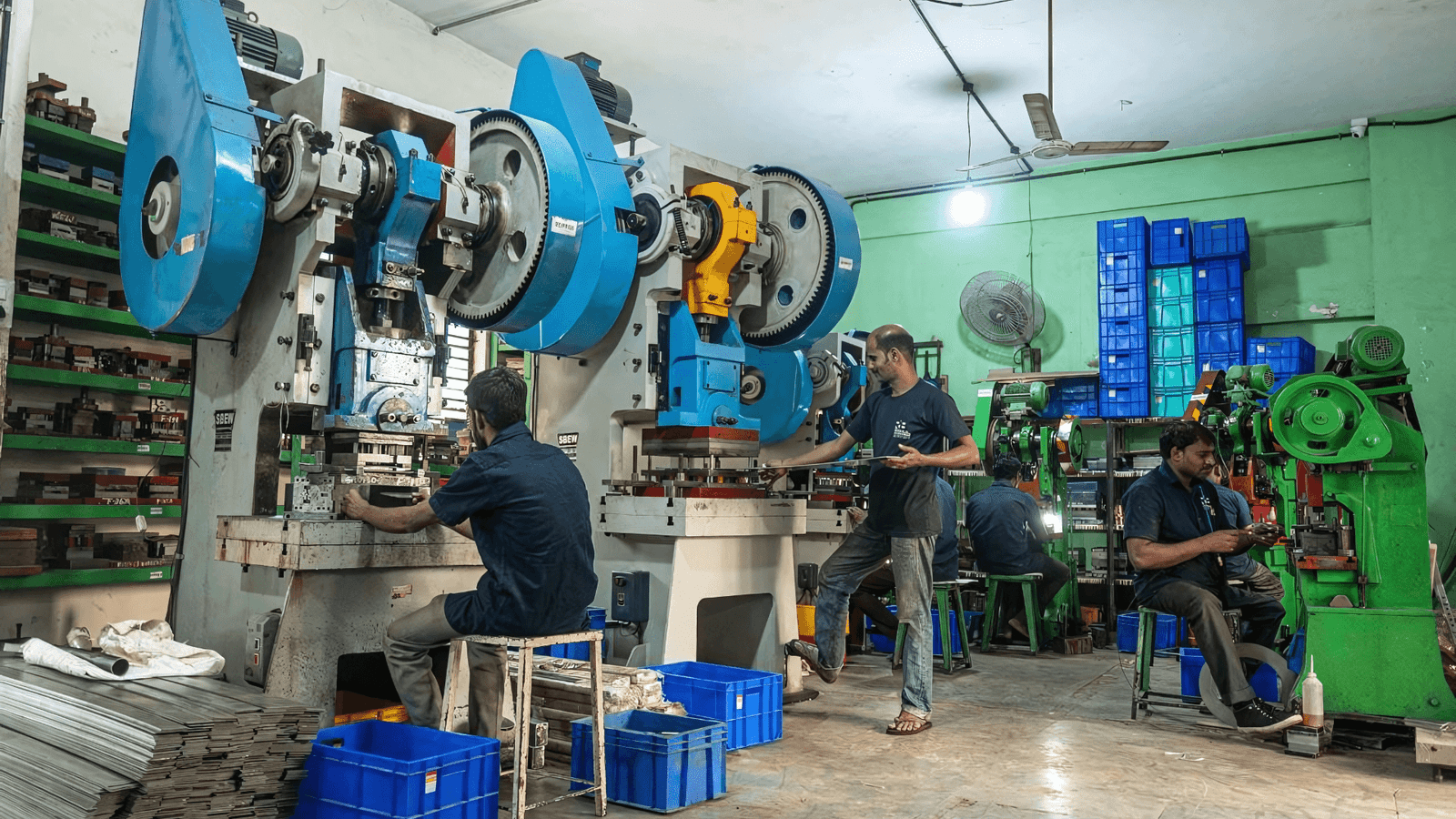

Powered by high-speed presses and expert tool design, we deliver consistent quality at scale.

Discuss your requirements with our experts and discover the perfect metal fabrication solution.

For over 25 years, Rahul Enterprises has led the way in precision metal stamping and tooling for automotive, electrical, electronics, and automation sectors. Built on integrity, innovation, and unmatched technical expertise, we transform sheet metal into excellence.

Trusted by leading OEMs and industrial clients for over two decades, Rahul Enterprises is the name behind millions of precision-engineered components that keep industries moving.

With decades of expertise and a commitment to quality, Rahul Enterprises delivers more than just parts — we deliver confidence. Here’s why clients choose us as their preferred manufacturing partner.

From concept to completion, we design and build all tools internally for unmatched accuracy and consistency.

Our streamlined manufacturing processes ensure high-volume delivery without compromising quality.

We prioritize your requirements and deliver fully customized sheet metal solutions that exceed expectations.

With over 10+ mechanical and high-speed presses and 3 million+ parts produced monthly, we’re built for scale.

Every product undergoes strict inspections using calibrated tools, gauges, and automated systems.

We follow environmentally conscious practices and efficient material utilization to reduce waste.

Led by seasoned engineers, our legacy is built on transparent communication and long-standing industry relationships.

Your designs and proprietary data are protected with strict internal security and NDA protocols.

We’re always here to assist — from design feasibility to post-delivery service.

At Rahul Enterprises, we don’t just manufacture components—we build long-term partnerships rooted in precision, performance, and trust. Discover why companies across the automotive, electronics, and automation sectors choose us as their go-to manufacturing partner.

From in-house tooling to high-speed precision stamping, Rahul Enterprises offers end-to-end sheet metal solutions tailored to your manufacturing needs.

From small intricate parts to large-volume runs, we provide high-speed, progressive stamping using copper, brass, aluminum, stainless steel, and more.

Our in-house toolroom designs and builds progressive, compound, rivet, and step tools with full control over every stage ensuring consistent quality.

With a monthly output of over 3 million parts and a growing fleet of power presses, we’re ready to scale with your production demands reliably and on time.

From custom tooling to high-volume stamping, we’re ready to turn your concepts into precision-engineered components. Partner with Rahul Enterprises

Chmer and Sodick machines are booked for 12 months through a tie-up with a vendor.